CONTENT

Where Does Coffee Come From?

Coffee beans are actually seeds from the fruit of coffee trees! These red or purple fruits are called coffee cherries or berries. Two oval-shaped beans can be found in one cherry.

But occasionally, due to a naturally occurring mutation, only 1 bean is present. That bean is termed a peaberry!

Once the cherries are picked, the process of harvesting the coffee beans begins. There are 3 main ways to process the coffee beans: natural, washed, and semi-washed.

Natural (Dry) Processed

Natural (or dry) processed is where the beans are dried in/together with the fruit before the outer layers are hulled and milled. This method is the oldest form of processing coffee beans, and it has its perks — for one, it is environmentally friendly.

Amongst the 3, it requires the least amount of water and steps. Because the coffee beans were in contact with the fruit for an extended period, they tend to be fruitier and fuller in body. This draws coffee lovers who seek these cupping notes.

Washed Processed

Washed coffee beans meant that the fruit gets de-pulped, and the remaining mucilage is broken down by microbes and yeast before they are washed off. After which, the drying process takes place.

Even though this method requires more steps and materials, for producers, it is a win as it is less labour-intensive and results in a cleaner and more consistent (flavour) yield. Coffee processed in this manner tend to exhibit higher acidity, brighter fruit flavours, lighter body, and classic nutty flavours.

Semi-Washed Processed

Semi-washed process (aka honey or wet-hulled) is the newest process of the three. Firstly, the fruit gets de-pulped and the outer skin removed. The beans are then dried with the mucilage still present, after which, they too are washed off.

The second drying step ensues (at varying degrees) before the beans are ready to be used. This method is said to increase the body and intensity of the flavour of the coffee.

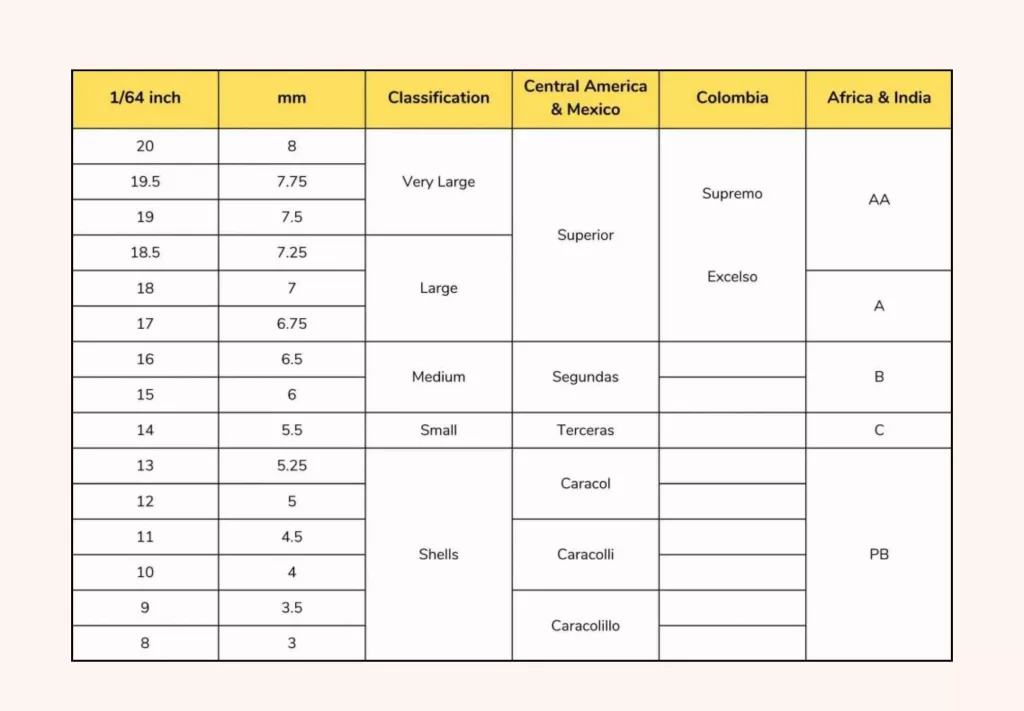

Grading And Sorting

From harvest to final drying, workers and machines have been doing their best to remove any defective beans. But, proper grading and sorting can only occur after the coffee beans have undergone their final drying step.

Many producers employ the use of coffee bean grading sieves to sort the beans according to their size. Some businesses may even use laser diffraction technology to sort their coffee beans.

Besides sorting the coffee beans according to their sizes, they are also graded by the number of defects, density, weight, moisture content, aroma, and purity.

The standard whereby coffee is sorted and graded can vary between countries, regions, and even between producers. One of the best ways to pick your favourite producer/seller/beans is by letting your senses (sight, smell and taste) do the choosing.

- Visually, check the beans for defects or signs of infestation

- Smell the aroma before and after brewing

- Taste (personal preference – though it should not taste off)

Exporting Coffee Beans

Once the sorting and grading have been completed, the green (unroasted) beans are then packed and shipped off to merchants. The most common packaging material used is gunny sacks (jute bags). These are strong enough to contain and protect the coffee beans during export. The downside is that they do not keep moisture out.

Some companies vacuum pack their beans, which helps slow down the degradation of the coffee beans during transit. The cost, however, is passed on to consumers.

Importance Of Sorting Coffee Beans Before Roasting

If the process of getting to this stage is not multi-faceted enough, you’d be amazed to know that the roasting step is just as instrumental in producing that final cuppa you drink.

Even after the coffee beans have been sorted and graded before export, good roasters still check the beans before roasting. They would check that most beans are of similar size and remove any defective bean that slipped through the system.

- It is important that most of the coffee beans are of similar size to achieve a more even roast within the batch.

- Roasters know that all it takes is one bad bean (e.g., off-coloured, insect damaged, mouldy, etc.) to ruin the taste of the coffee we drink

After prepping their batch of beans, roasters then roast the beans according to a set of parameters specific to the type of coffee beans. Coffee roasting is a delicate process which requires skill that takes years of training, practice, and experience.

Takeaway Message

The process of bean/cherry to cup is such an extensive affair that the information on this page only covers a fraction of what actually takes place. It does not even touch on the arduous task of cultivating coffee plants!

Suffice it to say, a lot of time, effort, and dedication go into the cup of coffee that we drink — a lot of times, mindlessly.

The next time we indulge in our cup of coffee, we could pause for a moment to appreciate the process of how it came to be.